They are a way of mounting the rubber flexographic plate on to a brass sheet, which is then curved in to a cylindrical shape. This in turn is placed on to (around) the Plate Cylinder and held in place with metal tension bands, they are like large Jubilee Clips.

The original reason for coming up with the Jiffy Mount (some called it the ‘Minute Mount’) back in the 1970’s was to enable the mounting of the rubber plate on a cylinder without the use of double sided adhesive tape (DSA). One of the main users of the J/M was the Hot Wax Carbon printers. It was used to apply a carbon ink to the back of tickets, cheques & documents that had multiple pages (parts) to them – like the old style airline tickets. A Dot Matrix printer would be used to print the information on to the ticket, transferring the information on to 4 or 5 other pages (parts).

To keep the wax carbon ink liquid it is heated and in order to stop the ink from cooling on the plate surface (solidifying) they pumped hot water through the hollow centre of the plate cylinder. The heat would have affected the adhesive in one of two ways. Either softening the adhesive, effectively melting it, at which point the printing plate would slide off the cylinder. The other was for it to dry out or baking the DSA rock hard, making it impossible to remove the plate at the end of the print run.

They are produced in the same way a standard rubber stereo apart from you add a sheet of bonding material and brass sheet before closing the press. Producing an order for 144 Jiffy Mounts has been an interesting period of re-learning for me, if not a little repetitive! I have been watching the production of J/M’s since the early 1980’s. Getting all of the variables just right can be like juggling live chickens! Causing trapped air between the brass and the rubber and trapped air between the rubber and the mould, meaning missing parts of the image, to mention just two.

This type of plate brings its own issues as the back of the finished plate cannot be ground down to the correct thickness or grind down high spots. To this end I have found the best way is to make a new mould in the press you are making the J/M’s in. then make your first J/M and mic-up (measure) the whole image area making notes direct on to the plate.

This will tell you 2 things, firstly if you have the correct overall thickness. This can be adjusted by adding or removing bearers from the press.

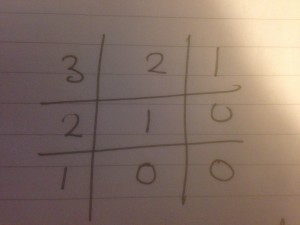

Secondly, the overall evenness of the plate. To adjust this divide the image area(on the back of the mould) in to a 9 box grid – like noughts and crosses. Transfer the figures from the plate to the grid. the more readings you have the better. Using these figures you can work out which grids need reducing in thickness.

Using the required plate thickness as Zero ‘0’ and then adding square grid size pieces of brown paper, one piece reduces the thickness by .002”/.003” in the grids that need reducing in thickness.

Using the above drawing as an example, you can see how to add the paper under the mould to reduce the thickness in the area necessary.

Once the plate has been cast and checked for thickness and flaws in the image you then square the image on the brass sheet and trim the 2 sides. At this point you only score the leading and trailing edges. Should you trim the leading and trailing edges you will end up with ‘flat’ areas when the plate is curved, as the Bender does not act on these areas as it does on the middles section of the plate. The 2 remaining edges are then removed and any burs are cleaned off.

Should there be a ‘next’ time. I will look at ways of sticking the paper to the back of the moulds. But finding an adhesive that does not add any thickness to the paper but will hold up to the temperature will be interesting. I am thinking of a spray mount type product.

If you would like to know more or have any questions or suggestions please use the reply box.