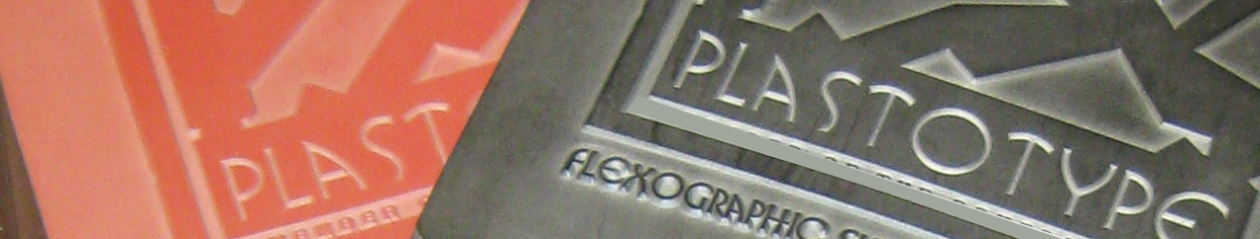

Our platemaking foundry can produce both standard and specialised rubber stereos.

The rubber compounds we use are sourced from leading manufacturers to ensure the exceptional standard of quality and plate surface properties.

In every case, we offer a fast turnaround and an unrivalled level of technical knowledge.

What is a Rubber Stereo?

A rubber stereo or ‘plate’ is produced using an un-vulcanized rubber compound. It is supplied in a sheet form, on a roll. The plates are used in the Flexographic printing industry. Where they are attached to the plate cylinder using a double sided adhesive tape of a flexographic printing press, which are web fed (continuous) presses.

The plate is ‘cast’ in a mould using a hot vulcanizing press.

The mould is produced by pressing a metal ‘master’ into a moulding board the using the hot press. The board is thermosetting, which means the board cures or sets after about 15 minutes. The mould can be used to produce many rubber stereos or ‘dups’.

One advantage that rubber stereos have over photopolymer plates is they can be made to any thickness the customer requires. Any unevenness in the plate can be reduced by removing a small amount from the back of the plate using a Back Grinder until the plate has the correct uniform thickness.